Instructions for pumping down the dewar

Checklist for experts -- others read below first!!

-

Place the vacuum pump cart on the square marked on the carpet. Put

the telescope at HA 6.5 hours W and Dec 30 degrees. Then connect the

pump cart's power strip to the UPS.

-

Before connecting the dewar valve to the valve actuator connected

to the vacuum system, clean and blow off both valves. Unscrew the

large nut on the end of the actuator a few turns to remove the

pressure from the O-ring. Align the actuator and dewar valve, then

slide the actuator over the valve on the dewar. Use the small black

wrench to tighten up, but don't yet engage the plunger which opens the

valve.

-

On the cathode controller, first make sure "filament" and "degas" are

switched off. Turn on both high and low pressure meters.

-

Gently open the main vacuum valve about xx turns.

-

Turn the pump on.

-

When the high pressure meter reads "0", turn the filament on.

-

When the pressure gets to around 8E-5 torr, engage the valve on the

dewar: push the plunger in slowly. When only about twice the taped-up

distance on the plunger rod is showing, you can start screwing the rod

into the plug. When it is fully screwed in, pull the plunger up very

slowly to crack the seal to the dewar. The seal is broken when

about 2 inches of the plunger show.

-

You are shooting for something on the order of 5E-5. This will take several hours. Shut the

filament off, and periodically turn it on to check the pressure. The pressure

fluctuates when the filament is turned on, however, and will take a bit to

equilibriate. So it is okay to leave the filament on, but just keep checking

it...

-

When you are satisfied with the pressure, push the plunger back down

into the dewar slowly. If you need to, rotate clockwise while

pushing, until only the taped-up part of the rod is showing. Then

close the main vacuum valve and unscrew the plunger rod from the plug,

moving the top of the plunger anti-clockwise with no outward motion.

Then pull the plunger out all the way. Then, turn the filament off,

the gauge power off, and the vacuum pump off. Disconnect the actuator

from the valve by unscrewing the large nut with the black wrench.

General comments

NEVER pump down the dewar when it is

cold. When it is cold, the vacuum inside is less than E-6 torr due to

cryo-pumping (molecules freezing onto the walls). Wait at least an

hour after the CCD has reached room temperature.

Our main priority here is to prevent the destruction of the CCD (the

most expensive bit). The blast of air and the shock wave caused by

rapid changes in pressure from evacuated to atmospheric pressure can

destroy the CCD, either by tearing off bond wires or shattering the

CCD surface itself.

Therefore we need to ensure that the dewar is fully closed before

disconnecting or turning off the vacuum pump. The vacuum pump can also

be destroyed by this blast of air, which can tear the vanes off the

turbo-molecular pump (just like the effect of throwing frozen chickens

into a jet engine).

Always put on clean rubber gloves when handling the vacuum pump fittings,

because even small bits of dirt or grease can contaminate the system

and/or cause vacuum leaks.

Connecting up the vacuum pump

-

Place the vacuum pump cart on the square marked on the carpet. Put

the telescope at HA 6 h 20m W and Dec 27.5 degrees. Then connect the

pump cart's power strip to the extension cord connected to the UPS

under the desk. This cord is labelled "UPS".

-

The next step is to connect the vacuum system to the dewar. Remove the

plastic cover from the dewar vacuum valve.

The next step is to connect the vacuum system to the dewar. Remove the

plastic cover from the dewar vacuum valve.

-

Wipe the surface of the

valve with a dry Kimwipe. You need to wipe all the bits that will be

inside when the valve actuator is connected: the rim, all of the

inside bits that are visible, and the part of the outside of the valve

that the actuator valve screws into. Blow off any dust with the air gun.

Remove the plastic cover from the valve actuator at the end of the

stainless steel vacuum pump hose. Gently wipe the inside of the

actuator (including the O-ring) with a Kimwipe and blow off any dust

with the air gun.

-

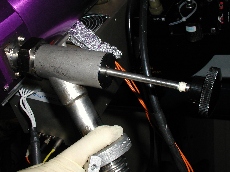

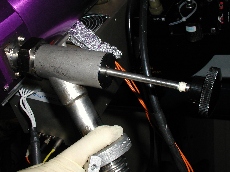

Unscrew the large nut on the end of the actuator a few turns to remove

the pressure from the O-ring so it can easily slide over the valve on

the dewar. Make sure the plunger is pulled out. Align the actuator and dewar

valve, and then gently slide the actuator over the valve on the dewar, as far as

it will go. Be careful not to scratch the dewar valve with the metal of the actuator.

Any scratches can cause a vacuum leak.

Unscrew the large nut on the end of the actuator a few turns to remove

the pressure from the O-ring so it can easily slide over the valve on

the dewar. Make sure the plunger is pulled out. Align the actuator and dewar

valve, and then gently slide the actuator over the valve on the dewar, as far as

it will go. Be careful not to scratch the dewar valve with the metal of the actuator.

Any scratches can cause a vacuum leak.

-

Use the small black wrench to tighten up (counter-clockwise when

looking down the plunger at the dewar). Hold the actuator assembly

with one hand while tightening the nut with the other, being careful

not to use too much force. When fully tightened, you will not be able

to move the actuator in or out, but it can still rotate with respect

to the dewar valve, and a tiny bit of wiggling is also allowable.

Tightening the nut squeezes the O-ring into a groove on the valve to

form the vacuum seal. This feels different from tightening a threaded

screw where metal contacts metal.

Don't yet engage the plunger which opens the valve. The valve

fittings (O-ring, etc) are very sensitive to dirt, so use caution when

handling them.

-

You may now need to adjust the position of the cart slightly to minimize

any twisting in the stainless-steel vacuum cable.

-

Now that we are properly connected, we can power up the vacuum

system. On the cathode controller, first make sure "filament" and

"degas" are switched off (middle position).

Now that we are properly connected, we can power up the vacuum

system. On the cathode controller, first make sure "filament" and

"degas" are switched off (middle position).

-

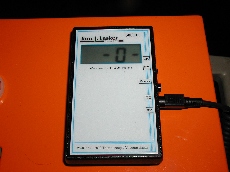

Turn on both meters. The little LCD one measures high pressure, the

bigger LED one (shown right) measures low pressure.

Turn on both meters. The little LCD one measures high pressure, the

bigger LED one (shown right) measures low pressure.

-

Gently open the main vacuum valve (which projects from the top of the

housing on the vacuum pump) about 10 turns. (Don't over-tighten

this valve either opening or closing it.)

Gently open the main vacuum valve (which projects from the top of the

housing on the vacuum pump) about 10 turns. (Don't over-tighten

this valve either opening or closing it.)

-

At this stage we will be pumping down the vacuum system and the stainless

steel line to the dewar, but not the dewar itself.

The reason we open the main valve at this stage is so we can get the

vacuum system to a higher vacuum than the dewar's before opening the

dewar valve. Whenever the dewar is on the telescope, it has a vacuum

inside; we always want any air movement to be OUT of the dewar to

protect the CCD and keep the dewar clean inside.

-

Double-check that everything has been done correctly, then turn

the pump on.

Double-check that everything has been done correctly, then turn

the pump on.

-

The backing pump starts first and produces a coarse vacuum. The yellow

LED below the on switch is on at this stage. You'll hear a click after a

few sec and hear the whine of the turbo-molecular pump spinning up to

27,000 rpm. When the pump has reached full speed the green LED will

light. If the red LED shows, turn off the the pump, wait a few

seconds, and try again.

-

When the high pressure meter reads "0", turn the filament (of the hot

cathode which operates the low pressure meter) on. This should

take a couple of minutes -- in the absence of the high pressure meter,

just wait a bit (as long as you are sure everything else is behaving normally!).

It's normal for the filament to fluctuate when it is first turned on. It

will automatically turn off if the pressure is above 5E-3 torr.

-

After a bit of fluctuation, the low pressure meter should start

showing a steady decrease in pressure. When it gets to around 8E-5

torr, engage the valve on the dewar as follows.

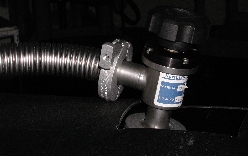

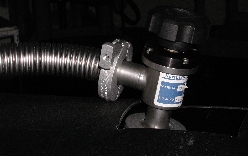

The fitting that connects the stainless steel vacuum hose to the dewar

has a plug with 2 O-rings around the outside:

The fitting that connects the stainless steel vacuum hose to the dewar

has a plug with 2 O-rings around the outside:

The plunger has a rod on the inside which screws into the plug and can

then be used to pull the plug out.

The plunger has a rod on the inside which screws into the plug and can

then be used to pull the plug out.

Moving the plunger on the dewar vacuum valve knocks off molecules

which can leak past the O-ring, so the pressure increases

temporarily. If you move it slowly, the vacuum pump can keep up.

Push the plunger in slowly.

When only about twice the taped-up distance on the plunger rod is

showing, you have reached the position where you can start screwing the rod

into the plug. You may need to wiggle the rod slightly to engage the

screw thread. When all you can see of the plunger rod is the taped-up

portion, you have screwed the plunger fully into the plug.

Then pull the plunger up very slowly to remove the plug from the

valve and hence crack the seal to the dewar itself. The seal is broken

when about 2 inches of the plunger show. You'll see the low pressure

meter jump up significantly (few E-3 torr).

-

You are shooting for something on the order of 5E-5. This will take

several hours. Shut the filament off, and then periodically turn it on

to check the pressure.

Disconnecting the vacuum pump

-

When you are satisfied with the pressure, push the plunger back down

into the dewar slowly, while watching the pressure.

Moving the plunger on the dewar vacuum valve knocks off molecules

which can leak past the O-ring, so the pressure increases

temporarily. If you move it slowly, the vacuum pump can keep up.

-

When only about twice the taped-up distance on the plunger rod is

showing, you have reached the position where you are seating the

plug-with-O-ring which is screwed onto the end of the rod in the

valve itself. If you can't push it in easily, rotate clockwise while

pushing, until only the taped-up part of the rod is showing.

-

When you have reached this hard stop,

you can check that the plug is in the valve and the rod is unscrewed

in two ways:

- you can wiggle the handle more freely in any direction

- if you push the rod back in, it will come to a hard stop with 1/4"

clear metal protruding.

While you are doing this, the vacuum pressure should have decreased

because you are only pumping the hose, not the dewar. We can use the

pressure as a final check that the dewar valve is closed following the

next step. Slowly unscrew the plunger rod from the plug, moving the

top of the plunger anti-clockwise with no outward motion. The rod

will unscrew about 1/4", and then you will feel it turning against the

top of the threads. If you have not managed to detach the rod from

the plug, you will notice at this stage that the pressure reading will

increase as you move the rod outwards. If the pressure remains

unchanged, just pull the plunger out all the way -- it should move more freely now.

-

Then close the main vacuum valve (thus protecting the vacuum pump).

Then, turn the filament off, the gauge power off, and the vacuum pump

off.

-

Disconnect the actuator from the valve by unscrewing the large nut

with the black wrench. Replace plastic covers on actuator and valve.

Don't move the cart until about 5 mins after the turbine has spun down.

[In future, add paragraph about bleeding air into system slowly using

a to-be-purchased bleed valve and watching pressure come up to 1 atm

on high-pressure meter.]

Troubleshooting

-

If the pressure continues to fluctuate by a factor of 5 or more after

several hours of pumping, there is probably a leak somewhere.

-

If the pressure does not drop much below few x 10-3, double check that

the turbine is in fact running. The green light should be lit on the

side of the pump.

-

You can check which side of the main vacuum valve (black handle

directly above the vacuum pump) the leak is on by closing it. If the

pressure decreases after closing, then the problem is on the dewar

side of the main valve. Next, push the plunger on the dewar vacuum

valve fully in. Open the main valve slowly. Is the vacuum reading

higher, or fluctuating slowly? If so, the leak is in the hose. If not,

the problem is in the dewar itself.

Table of Contents

Last Updated: April 2003

The next step is to connect the vacuum system to the dewar. Remove the

plastic cover from the dewar vacuum valve.

The next step is to connect the vacuum system to the dewar. Remove the

plastic cover from the dewar vacuum valve.

Unscrew the large nut on the end of the actuator a few turns to remove

the pressure from the O-ring so it can easily slide over the valve on

the dewar. Make sure the plunger is pulled out. Align the actuator and dewar

valve, and then gently slide the actuator over the valve on the dewar, as far as

it will go. Be careful not to scratch the dewar valve with the metal of the actuator.

Any scratches can cause a vacuum leak.

Unscrew the large nut on the end of the actuator a few turns to remove

the pressure from the O-ring so it can easily slide over the valve on

the dewar. Make sure the plunger is pulled out. Align the actuator and dewar

valve, and then gently slide the actuator over the valve on the dewar, as far as

it will go. Be careful not to scratch the dewar valve with the metal of the actuator.

Any scratches can cause a vacuum leak.

Now that we are properly connected, we can power up the vacuum

system. On the cathode controller, first make sure "filament" and

"degas" are switched off (middle position).

Now that we are properly connected, we can power up the vacuum

system. On the cathode controller, first make sure "filament" and

"degas" are switched off (middle position).

Turn on both meters. The little LCD one measures high pressure, the

bigger LED one (shown right) measures low pressure.

Turn on both meters. The little LCD one measures high pressure, the

bigger LED one (shown right) measures low pressure.

Gently open the main vacuum valve (which projects from the top of the

housing on the vacuum pump) about 10 turns. (Don't over-tighten

this valve either opening or closing it.)

Gently open the main vacuum valve (which projects from the top of the

housing on the vacuum pump) about 10 turns. (Don't over-tighten

this valve either opening or closing it.)

Double-check that everything has been done correctly, then turn

the pump on.

Double-check that everything has been done correctly, then turn

the pump on.

The fitting that connects the stainless steel vacuum hose to the dewar

has a plug with 2 O-rings around the outside:

The fitting that connects the stainless steel vacuum hose to the dewar

has a plug with 2 O-rings around the outside:

The plunger has a rod on the inside which screws into the plug and can

then be used to pull the plug out.

The plunger has a rod on the inside which screws into the plug and can

then be used to pull the plug out.